Anti-static rubber mats serve as core materials for controlling electrostatic hazards in industries such as electronics, semiconductors, chemicals, and precision manufacturing. The ESD Rubber Mat efficient static dissipation, material compatibility, and environmental adaptability significantly enhance production safety and product yield.

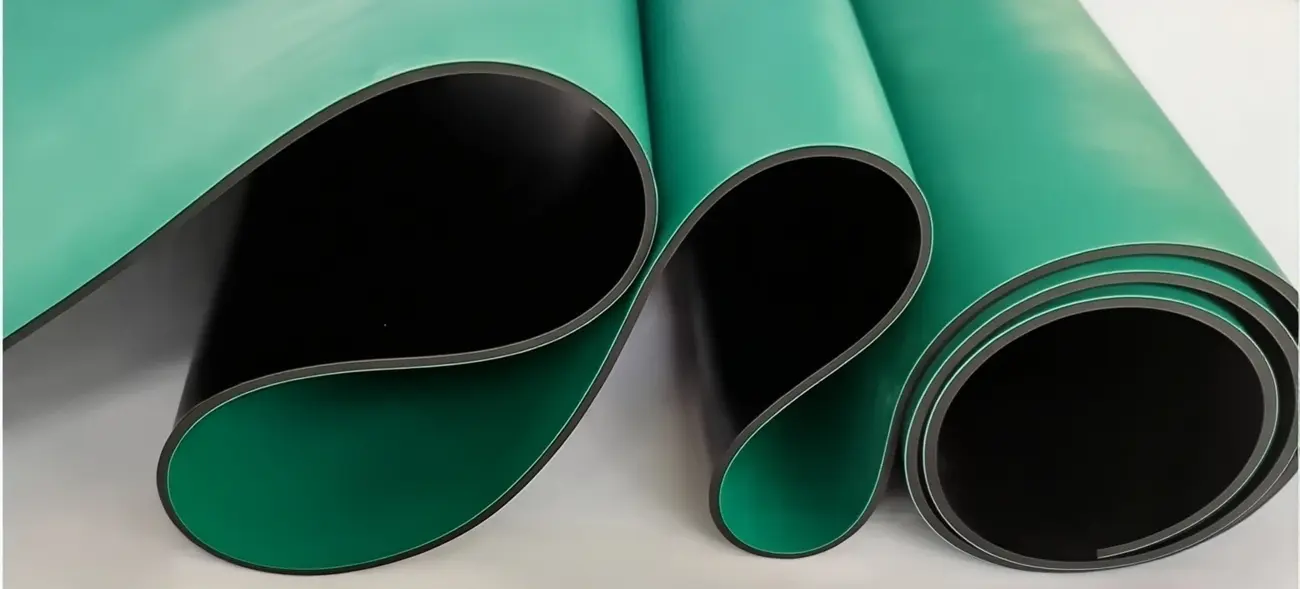

Anti-static Rubber Sheet ESD Floor Mats Rolls

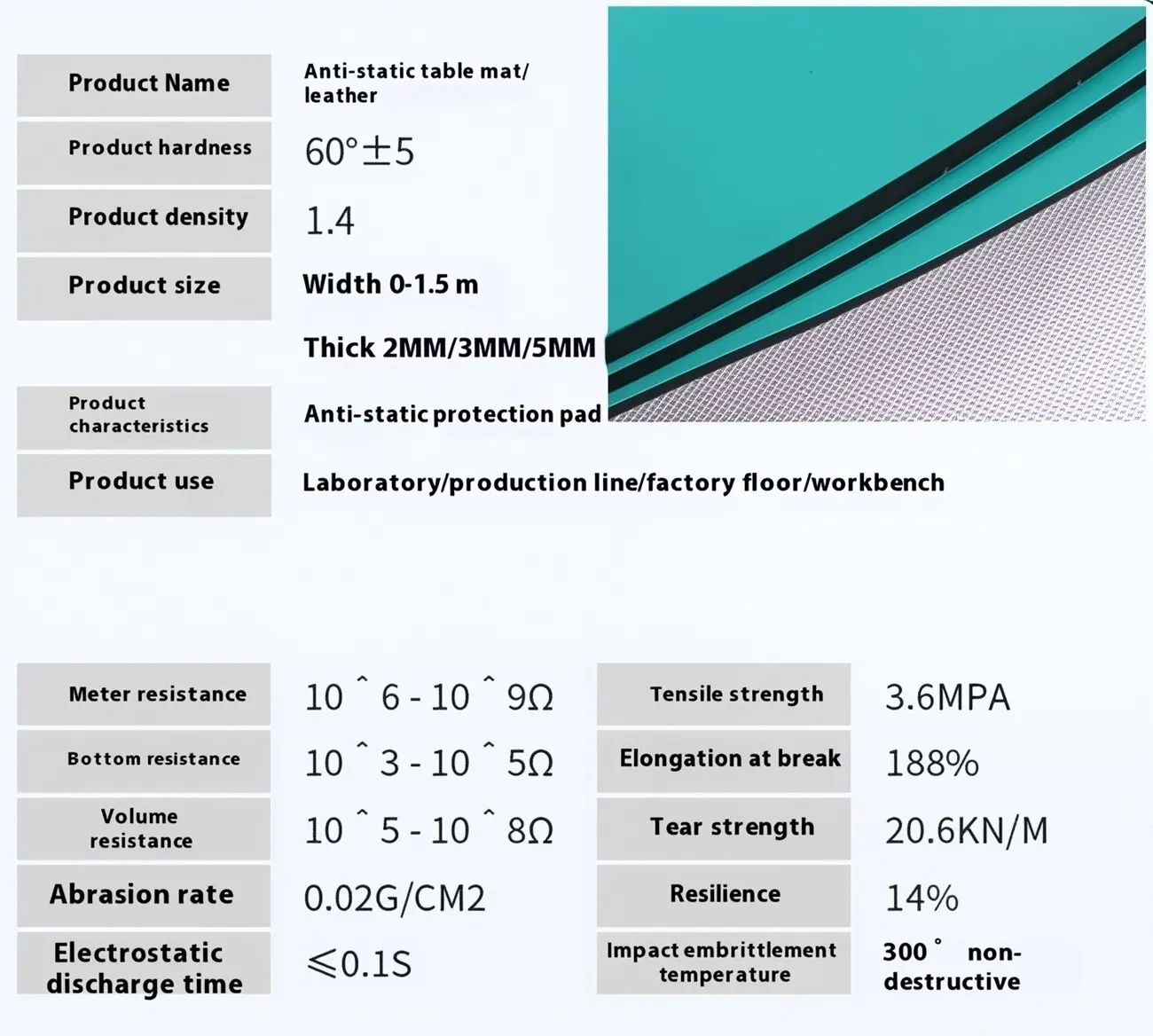

Green Odorless 2mm 3mm 5mm Anti-Static Rubber Mats Laboratory Desk Pads Factory Direct Supply ESD Floor Sheets for Electrostatic Protected Areas

Antistatic resistance value 10E6-10E9 ohm

Environmentally and health compatible

Extremely hard-wearing and very durable

Simple and economical to maintain

Safety, comfort and design for well-being

ESD anti static rubber floor mats Description

Main Function of Anti-static Rubber Mat

Discharge the static electricity of the human body, so that the human body and the tweezers, tools, appliances, meters and other

articles used in the work reach a uniform potential, so that the static-sensitive devices in the production are not interfered by

the phenomenon of electrostatic discharge and achieve the effect of electrostatic protection. Effective buffer and avoid device damage.

Anti static rubber sheet Feature

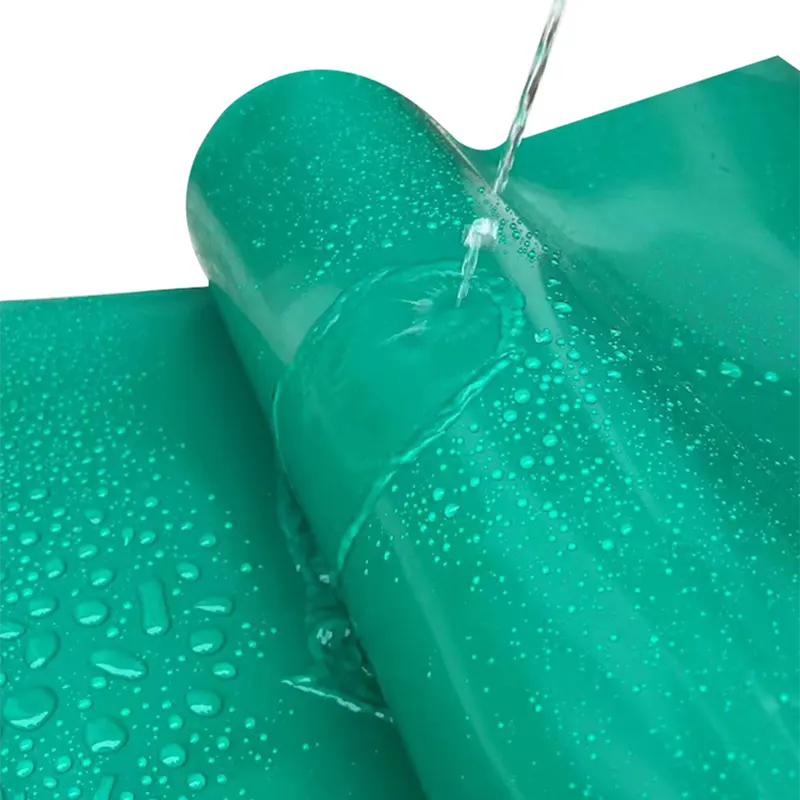

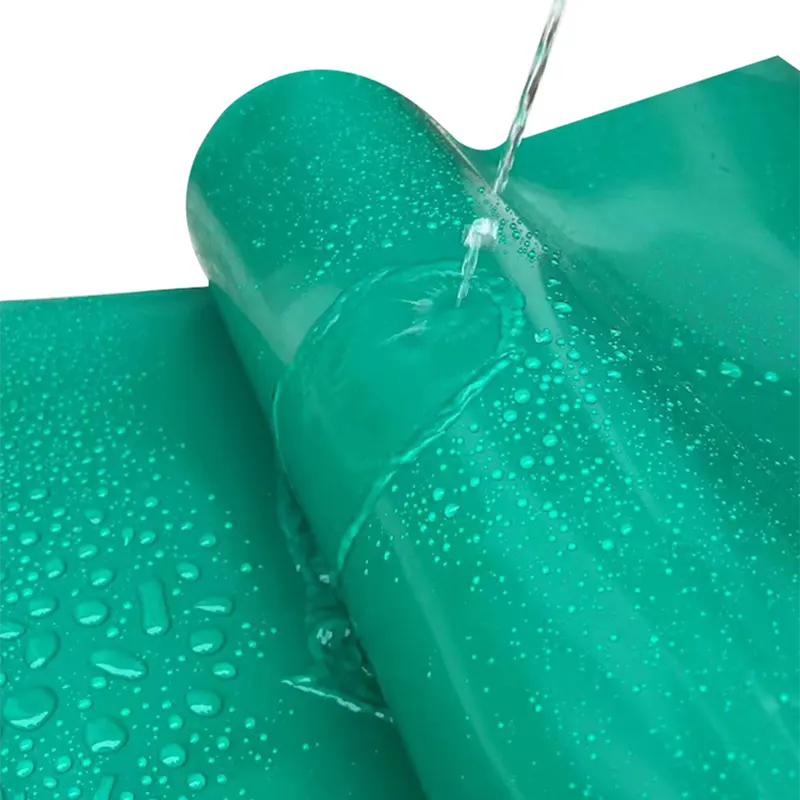

The anti-static rubber Plate is soft, strong in rebound, tear-resistant, wear-resistant, easy to clean, not interfered by factors such as high temperature, cold and humidity, and has a stable technical index.

ESD Anti-static Rubber Mats Advanced technology, elaborately made to meet the requirements of modern people’s work comfort.

1, Permanently anti-static.

2, Flexible, strong rebound, easy to clean, easy to move.

3, The surface of the steel pattern or spherical pattern anti-slip design, secure.

4, Acid and alkali solvents.

5, Isolate the cold, reduce vibration, and protect products and tools that are dropped during operations from damage.

6, Reduce production costs, improve employee health index and safety factor

7, Relieve blood pressure in the foot, reduce physical fatigue by 50%, and improve work efficiency by more than 30%

Anti Static Rubber Sheet mats for Electronics Data:

Anti-Static ESD Grounding Mats Suitable for anti-static workplaces that need to stand for a long time to effectively buffer foot pressure and relieve fatigue. The related data as follows:

| Product Name | ESD rubber mat Anti-static Rubber Sheet |

| Brand | Rifertech |

| Country of origin | Guangdong ,China |

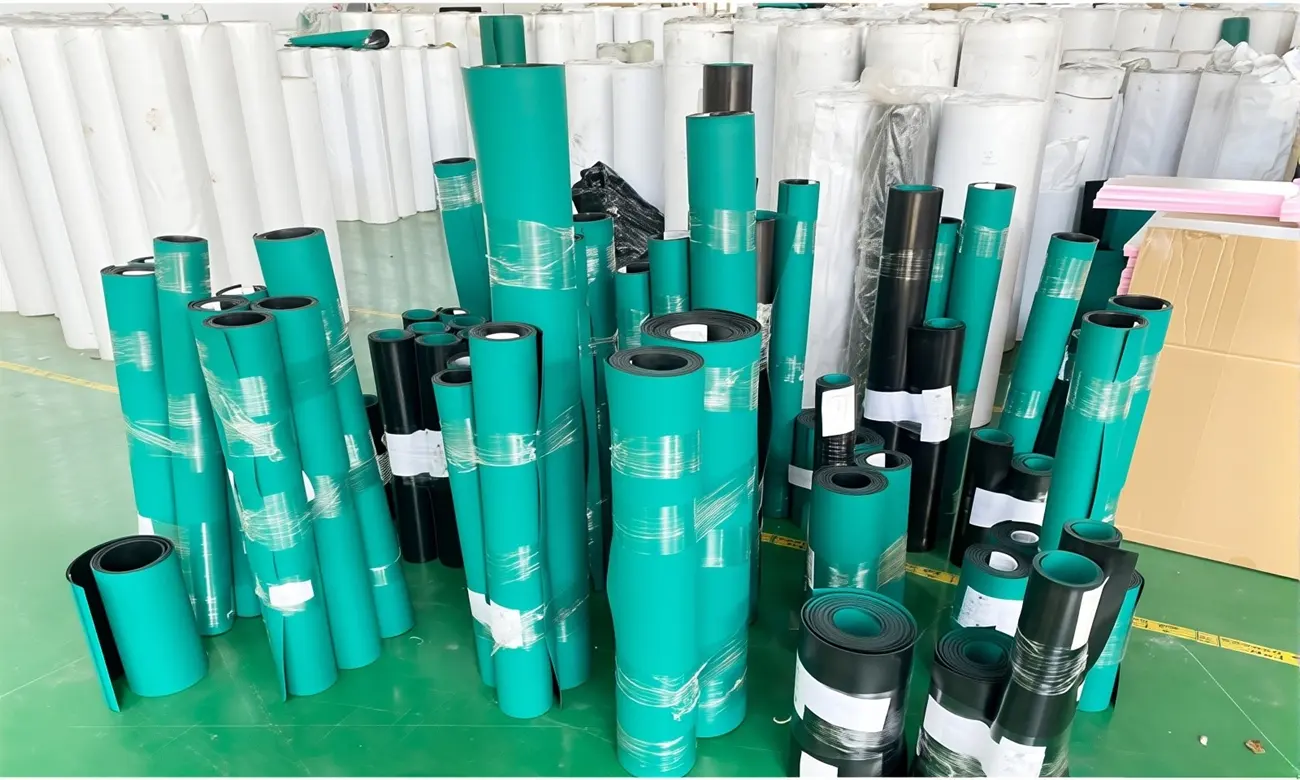

| Marketing Type | Manufacturer, wholesaler |

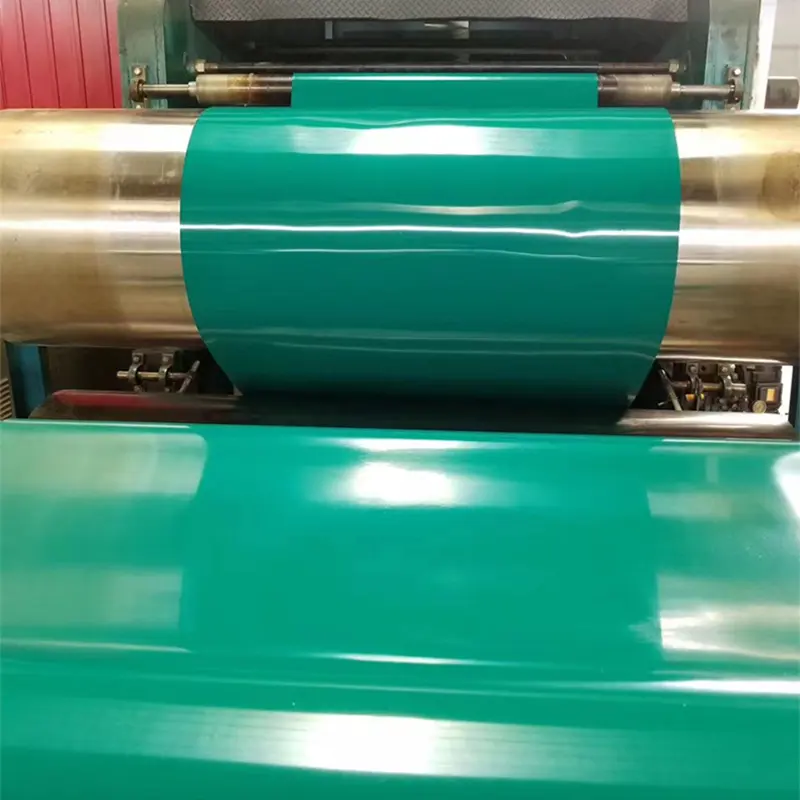

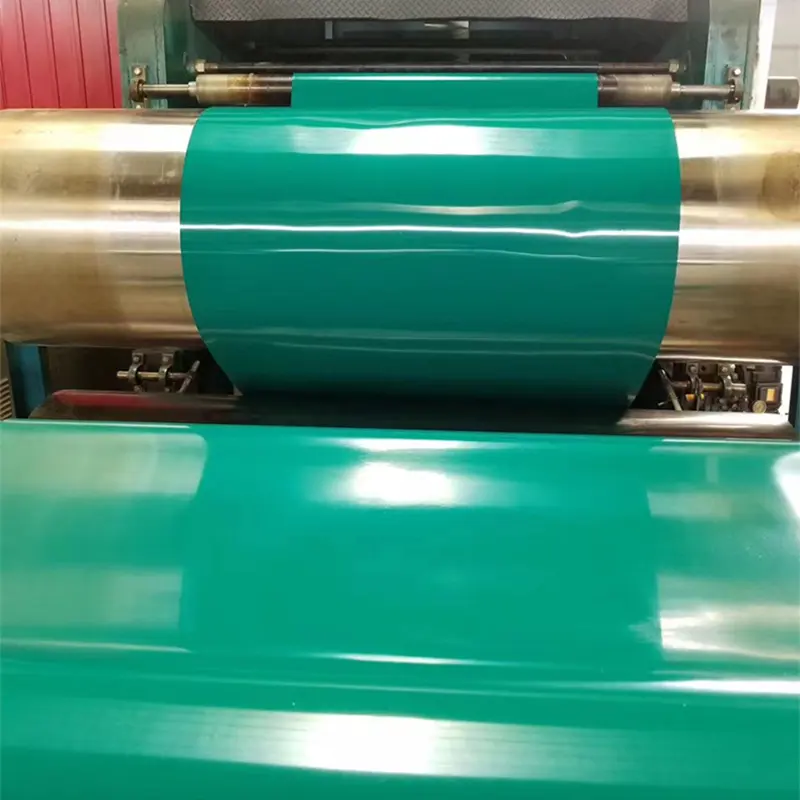

| Type | rubber sheet or Rubber Roll |

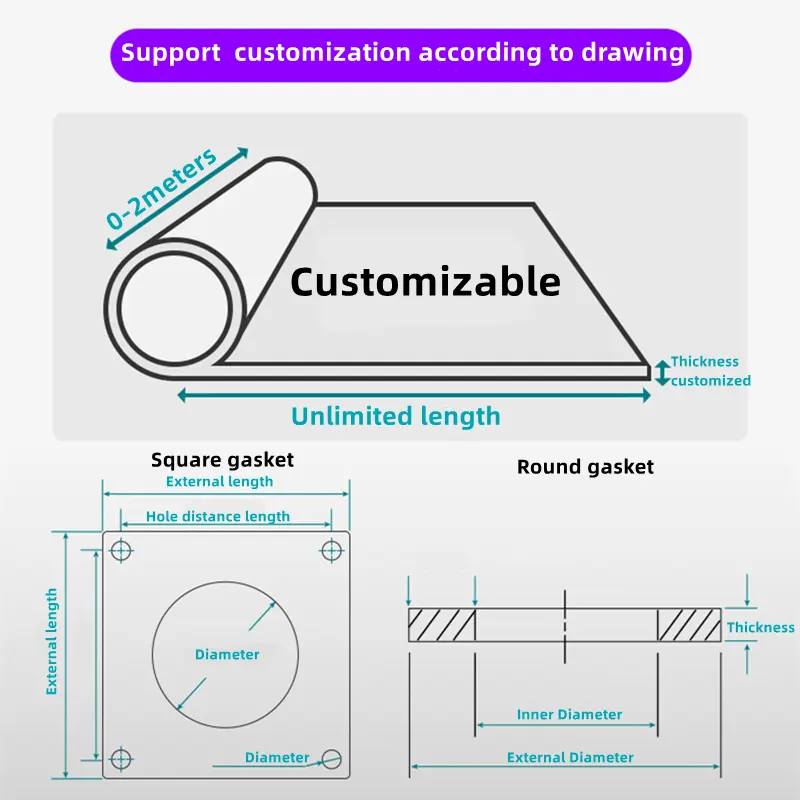

| thickness | 2mm, 3mm, 5mm |

| Hardness | 65±5 shore |

| Material | ESD rubber |

| Production Process | moulding , cutting |

| Size | Normal or Customized |

| working temperaure | -20 to 250°C |

| Sample | Free |

Get Free Quote Of Anti Static Rubber Sheets

Products Categories

Get A Free Quote

Main Applications of ESD Anti-Static Rubber Mats in Production

Anti-Static ESD Grounding Mats use for Electronics and Semiconductor Production

1. ESD Anti-static Rubber Mats for Workbench and Assembly Line Protection

Application Scenarios: Assembly workbenches for electronic components (e.g., chips, circuit boards, LED devices), SMT chip mounting production lines, PCB soldering stations, and semiconductor wafer handling platforms.

Core Functions:

Static Dissipation: Conductive materials (e.g., rubber with carbon black or metal fibers) rapidly ground static electricity generated by humans or equipment (surface resistivity typically \(10^6–10^9 \Omega\)), preventing electrostatic discharge (ESD) that could damage components (e.g., MOS transistors, integrated circuits).

Insulation and Cushioning: The insulating surface prevents electric leakage, while the mat cushions impacts to protect fragile components (e.g., glass substrates, ceramic capacitors).

Cleanliness Maintenance: Smooth surfaces reduce dust adsorption, and compatibility with sticky mats meets cleanroom (Class 100–10000) requirements (e.g., semiconductor packaging and testing workshops).

2. ESD rubber Mat Roll be used for Floor Anti-Static Coverage

Application Scenarios: Workshop passages, equipment bases, and shelf bottoms in electronics factories.

Core Functions:

Eliminates friction-generated static from personnel walking or equipment moving, preventing static transfer to products via shoes or wheels (enhanced by grounding clips).

Wear-resistant and easy to clean, suitable for high-traffic areas or trolley passage (e.g., material transport routes in lithium-ion battery production lines).

ESD Anti-static Floor Mat use for Printing and Packaging Industry

1. Anti-Static Workstation Mats use in Printing Equipment Workstations

Application Scenarios: Unwinding/rewinding stations of flexographic or screen printing machines, paper cutting tables.

Core Functions:

– Prevents static from attracting dust or lint to paper/film, avoiding printing defects (e.g., spots on packaging films).

– Reduces electrostatic repulsion between materials during high-speed printing, ensuring registration accuracy (critical for high-precision film printing).

2. Anti-static Rubber Sheet Roll use for Packaging Material Handling

Application Scenarios: Packaging workshops for electronic components (e.g., anti-static bags, blister tray production stations), mold workstations for plastic injection machines.

Core Functions:

Prevents static generation during plastic particle or finished product friction, avoiding impurity adsorption or material adhesion (e.g., packaging of precision gears or optical lenses).

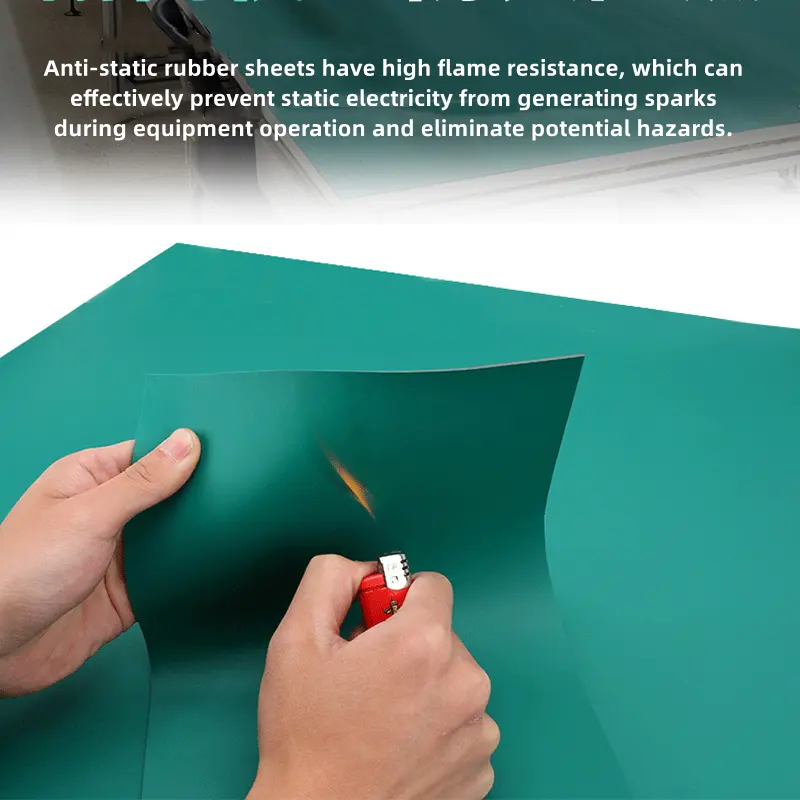

ESD Rubber Mat For Workbench use in Chemical and Flammable/Explosive Environments

1. Anti static floor mat for Hazardous Chemical Handling Stations

Application Scenarios: Solvent mixing tables, filling lines, storage areas for flammable/explosive materials (e.g., alcohol, gasoline, dust environments).

Core Functions:

Explosion-Proof Safety: Conductive mats rapidly discharge human static to eliminate spark risks that could ignite flammable gases or dust (surface resistivity ≤ \(10^6 \Omega\), compliant with ATEX standards).

Chemical Resistance: Materials like nitrile rubber (NBR) or fluoroelastomer (FKM) resist solvent erosion (e.g., acetone, xylene), extending mat lifespan.

2. ESD floor mat grounding for Pipeline and Equipment Grounding Auxiliary

Application Scenarios: Reaction kettle workstations, maintenance platforms for flange connections in oil pipelines.

Core Functions: Supplements grounding systems to ensure no residual static on equipment surfaces, reducing explosion hazards.

ESD mat for workbench for Precision Instruments and Optical Manufacturing

1. Inspection and Calibration Workbenches

Application Scenarios: Operation platforms for coordinate measuring machines, spectrometers, microscopes, and optical lens coating lines.

Core Functions:

Prevents static from attracting airborne dust particles, avoiding contamination of precision instrument sensors or optical components (e.g., dust on lens surfaces affecting imaging quality).

Low-outgassing design (silicone-free, halogen-free) prevents organic vapor emissions from polluting testing environments (suitable for semiconductor wafer inspection labs).

2. Magnetic Recording Material Production

Application Scenarios: Magnetic head assembly stations for hard disks/tape drives, magnetic powder coating production lines.

Core Functions:

Eliminates electrostatic interference with magnetic powders, avoiding uneven magnetic layer distribution that causes read-write errors (e.g., reduced storage density in hard disks).

Anti static rubber flooring mat Key Performance Requirements and Selection Criteria

1. Static Parameters

Surface Resistivity: \(10^6–10^9 \Omega\) (semi-conductive type for electronics), ≤ \(10^6 \Omega\) (conductive type for flammable environments).

Frictional Charging Voltage: ≤ 100V (ASTM D257 standard) to ensure the material itself generates minimal static.

2. Physical Properties

Temperature Range: -40℃~+120℃ ( general rubber); silicone rubber (-60℃~+200℃) for high-temperature environments.

Thickness: 2–5mm (for workbenches), 5–10mm (for floors, balancing cushioning and load-bearing capacity).

3. Installation Methods

Grounding Connection: Connected to the workshop grounding system via copper foil grounding wires (ground resistance ≤ 10Ω) for effective static discharge.

Fixing Methods: Adhesive backing (for smooth surfaces), snap-fit splicing (for large-area floors), and edge binding to prevent curling.

Anti Static Desk Mat Typical Industry Cases

Case 1: PCB Circuit Board Factory

Laying anti-static mats with \(10^8 \Omega\) surface resistivity at component insertion stations, combined with ionizers, reduced ESD-induced defect rates from 5% to <0.1%.

Case 2: Lithium-Ion Battery Production Workshop

Using electrolyte-resistant (carbonate-based) anti-static mats at the winding stations of electrode coating machines, preventing dust adsorption on aluminum foil that could cause battery short circuits.

Case 3: Aerospace Precision Machining

Installing low-outgassing anti-static mats on precision grinding workbenches for titanium alloy parts, eliminating static interference with high-accuracy sensors like laser rangefinders.

ESD anti-static rubber plate sheet Details Display

Related Products

Related News

Classification and Selection of Rubber Sheets Abstract This paper systematically classifies rubber sheets based on material composition, functional properties, […]

Ⅰ.Production of Polyurethane Rubber Roller Parts and PU Components The production process of polyurethane rubber roller parts and PU components […]

I. Demand Communication and Confirmation Understanding Needs: Conduct in-depth communication with customers to understand their operating environment, process requirements, material […]